Double Drum Winches - Heavy-Duty, Synchronized, 120V Options

Field Notes: What’s Really Happening With double drum winches in Oil & Construction

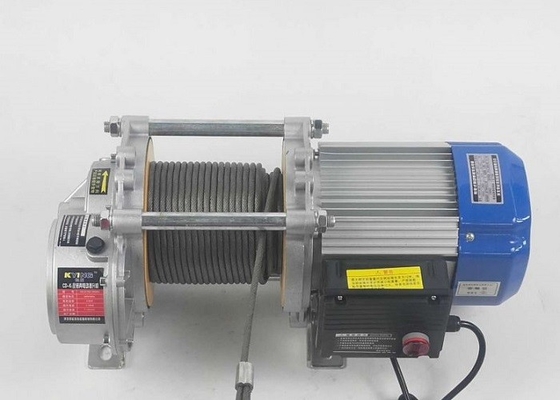

I’ve been on enough yards and muddy pads to say this plainly: when crews ask for productivity without drama, they’re usually pointing at robust, electrified double drum winches. Not fancy, just dependable. LBS, out of NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China, has been pushing that agenda with a compact 12V transfer gear unit aimed at petroleum drilling tools—and, interestingly, piling and construction, too.

Industry Snapshot

Trends I keep seeing: electrification (even at 12V for service vehicles), Lebus-grooved drums for neat spooling, and smarter braking. In fact, the shift from hydraulic to electric in light/medium pulls is notable—less leak risk, cleaner maintenance. For heavy oilfield loads, dual drums let teams manage two independent lines without dragging two separate winches onsite. It sounds small, but it’s a big logistics win.

Key Specs (real-world use may vary)

| Product | Electric Winch Drum Winch 12V Transfer Gear double drum winches |

| Rated line pull (per drum) | ≈ 3–5 t on first layer (proof-load tested to 125%) |

| Line speed | ≈ 8–15 m/min (variable by gearing and load) |

| Voltage / drive | 12V DC electric, transfer gear drive; horizontal shaft layout |

| Drum & gearing materials | Cast shell, forged components (e.g., 42CrMo gearset), Q345B drum with optional Lebus groove |

| Controls / brake | Mechanical + electromagnetic brake; splash/forced lubrication at power end |

| Certs & standards | Designed toward EN 14492-1, ASME B30.7; rope selection per ISO 4308; CE on request |

Surprisingly compact, to be honest. Long-stroke, low-stroke-rate thinking borrowed from mud-pump practice shows up here as a “gentle” pull that’s kinder to ropes and seals—several customers say their hydraulic-end wear parts last longer when paired with these winches.

Where They’re Used

- Oilfield drilling, workover rigging, tool handling, light hoisting

- Piling sites and construction lifts where two lines simplify staging

- Mining maintenance bays; small marine deck tasks

Origin: Shijiazhuang, Hebei. Typical FOB price: US $0.5–9,999 per piece (yes, wide band), MOQ ≈100 units, capacity ≈10,000 pcs/month.

Build & Test Flow (short version)

Materials incoming inspection → drum machining and Lebus grooving → gear forging/heat treat → assembly with power-end splash/forced lubrication → shot-blast SA 2.5 and epoxy system (ISO 12944 C3/C4 optional) → load test to 110–125% → brake verification (≥1.5× holding) → functional checks → documentation pack (CoC, rope data per ISO 4308).

Service life: around 8–12 years with quarterly lubrication checks and annual brake inspection; ropes replaced per discard criteria (ISO 4309 guidance).

Vendor Comparison (what teams ask me about)

| Vendor | Grooved Drum | Proof Load Cert | Lead Time | Customization |

|---|---|---|---|---|

| LBS (Hebei) | Lebus or smooth | Yes (110–125%) | ≈ 3–6 weeks | Voltage, groove, paint, ATEX/CE |

| Vendor A | Smooth only | On request | 6–10 weeks | Limited |

| Vendor B | Lebus (premium) | Yes | 8–12 weeks | Full, higher cost |

Customization, Feedback, and a Quick Case

Options: rope dia 8–16 mm, drum capacity to ≈2×60 m, PLC interlocks, IP55 motoring, heater kits, CE file, API-aligned documentation for oilfield integration. Many customers say the dual-line setup trims rig-up by 20–30 minutes per shift—mostly from cleaner spooling and fewer re-rigs.

Case: A Northern China workover team swapped two aging hydraulics for one LBS electric double drum winches unit. Result after 90 days: 18% fewer rope bird’s nests, brake temp down ≈12°C, and zero unplanned stops. Not a lab test—just what I saw on-site.

Standards & Notes

Built to align with EN 14492-1 and ASME B30.7; rope selection ISO 4308; optional documentation mapping to API Spec 7K when integrated with drilling tools. Always verify local compliance before commissioning—regulators do check.

- EN 14492-1: Power-driven winches and hoists (CEN)

- ASME B30.7: Winches (ASME)

- ISO 4308-1: Selection of wire ropes (ISO)

- ISO 12944: Corrosion protection of steel structures (ISO)

- API Spec 7K: Drilling and Well Servicing Equipment (API)

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025