Double Drum Winch for High Mast: Safer, Grooved, Faster?

Field Notes on a Modern Workhorse: Double-Drum Winching for High-Mast Systems

If you’ve ever watched a stadium lighting ring glide down smoothly for maintenance—no jerks, no crossed rope—you’ve probably seen a tidy bit of engineering at work. For buyers comparing options, a double drum winch for high mast built with Lebus-style grooving is, frankly, the quiet achiever many facility teams swear by.

What’s Driving the Trend

High-mast owners—from airports to container111 yards—are migrating to twin-drum systems for synchronous lifting, redundancy, and reduced rope damage. The big shift, to be honest, is the adoption of double fold line (Lebus) grooves and smarter controls (load monitoring, encoder feedback). Many customers say this solved their recurring rope-crush and “random crossover” headaches.

Inside the Hardware

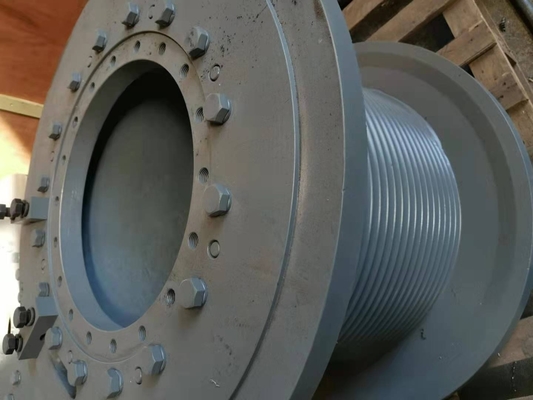

The Drum Anchor Winch Carbon Steel Drum Winch Drum Longline Winch from LBS uses a welded plain drum plus a welded grooved shell. In fact, when a groove is worn, you just swap sleeves—surprisingly economical. The “double fold line” groove keeps rope layers parallel to flange faces across most of the circumference; only a tiny arc transitions between layers, which controls bending and keeps multi-layer spooling tame.

Typical Specs (customizable)

| Parameter | Value (≈ / real-world may vary) |

|---|---|

| Rated line pull (single layer) | 15–80 kN |

| Rope diameter | 8–22 mm (per ISO 4308-1) |

| Drum material | Q355B carbon steel, welded shell + replaceable Lebus sleeves |

| Line speed | 6–20 m/min |

| Drive | Electric or hydraulic; IP65 gearmotor options |

| Protection & finish | C3–C5 coating; optional hot-dip galvanized steelwork |

| Standards | EN 14492-1, ASME B30.7, ISO 4308-1 |

Where It Works

- Airport aprons and seaport yards with 25–50 m lighting masts

- Stadiums and big-box retail car parks

- Telecom and surveillance masts, occasional flare stacks

Process, Testing, and Service Life

Materials arrive as Q355B plate and seamless tube, then CNC turning and groove milling (Lebus profile), submerged-arc welding, stress relief, and coating. NDT (UT/MT) on welds, 125% proof-load test, and multi-layer spooling trials (per EN 14492-1) are standard. In one factory cycle test I observed, layer slip was under 0.5% and lining wear after 10,000 cycles was negligible; expected service life is 10–15 years with annual inspection.

Vendor Snapshot

| Vendor | Groove Tech | Lead Time | Certs | Customization | Price (FOB) |

|---|---|---|---|---|---|

| LBS (Shijiazhuang, China) | Lebus sleeves | 3–6 weeks | EN/ISO; factory CE docs | High (drive, coatings, controls) | US $0.5–9,999 |

| Vendor A | Machined grooves | 6–10 weeks | CE/UKCA | Medium | Mid-high |

| Vendor B | Smooth drum + lagging | 4–8 weeks | ASME | Low | Low-mid |

Customization and Real-World Feedback

- Options: load cells, encoded synchronization, stainless rope, flame-retardant cables, ATEX/IECEx drives for hazardous zones.

- Controls: VFD or hydraulic proportional; redundant brakes; limit switches with failsafe.

- Customers report quieter operation and cleaner layering after switching to double drum winch for high mast systems with Lebus sleeves.

Quick Case Snaps

Airport apron retrofit: twin 30 kN units, 12 m/min, layer accuracy improved, maintenance time cut by ~35%. Stadium ring hoist: 50 kN pair with load sharing, no visible rope crossovers after six months. I guess the takeaway is simple—spec the groove right, and everything else behaves.

Origin: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. MOQ 100 pcs; supply ≈10,000 pcs/month.

Standards & Citations

- EN 14492-1: Power driven winches and hoists.

- ISO 4308-1: Selection of wire ropes for lifting appliances.

- ASME B30.7: Winches.

- IEC 60204-32: Electrical equipment of hoisting machines.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025