Double Drum Winch for High Mast – Synchronized, Heavy-Duty

Field Notes: building a reliable double-drum system for high-mast work

If you’re sizing a double drum winch for high mast lighting or beacon maintenance, you already know the stakes: small deviations up top can become big problems 50 meters in the air. Over the past few years I’ve watched buyers shift from generic drums to Lebus-style grooved sleeves because, to be honest, multilayer spooling is unforgiving. This piece pulls together what’s working in the field right now, plus some straight‑talk specs.

Why double drums on high masts?

Two drums let you split tasks: one for the primary hoist line, one for counterbalance, tools, or a safety/lifeline. In practice, operators tell me it eases maintenance of stadium lights, telecom masts, and navigation beacons. The Lebus double-fold-line groove (parallel in most circumference, intersecting near the flange) keeps the rope disciplined in tight layers—less crushing, fewer crossovers, better service life. Many customers say it just “spools calmer,” which sounds unscientific but, surprisingly, correlates with cleaner layers and fewer rope damage tickets.

Product snapshot

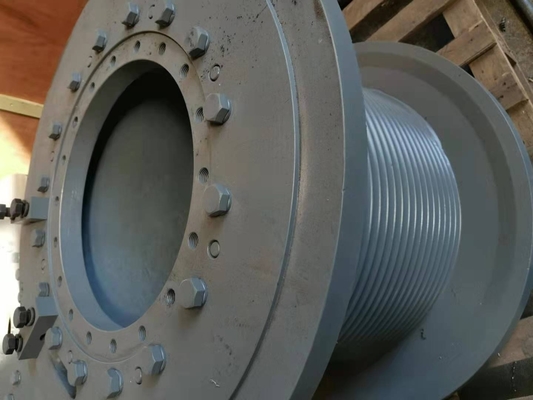

Drum Anchor Winch Carbon Steel Drum Winch Drum Longline Winch — origin: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. A typical Lebus built drum pairs a welded plain drum with a replaceable grooved shell; when wear happens, swap sleeves, not the whole drum. Sensible.

| Parameter | Spec (≈ / typical) |

|---|---|

| Drum material | Q355B carbon steel, welded shell + Lebus grooved sleeve |

| Line pull | ≈ 10–50 kN per drum (real-world use may vary) |

| Rope diameter | 6–16 mm (ISO 2408 wire rope) |

| Layer capacity | Up to 6 layers; groove optimized for fleet angle 0.5–1.5° |

| Drive | Electric or hydraulic; VFD available for soft starts |

| Coating | Sa2.5 blast + epoxy/polyurethane (ISO 12944 up to C5‑M) |

| Testing | Proof load 1.25×, functional test, NDT (UT/MT) on weld zones |

| FOB / MOQ | US $0.5–9,999 per piece; MOQ ≈100; capacity ≈10,000 pcs/month |

Process and verification

Materials: Q355B plate, low‑hydrogen weld wire. Methods: CNC-rolled shells, precision groove machining, sleeve shrink-fit or welded per procedure. Tests: UT/MT on circumferential seams; drum balance; 8‑hour continuous run at nominal load; brake hold at 1.25×. Typical service life? Around 10–15 years with rope management per ISO 4309 and yearly inspections. Industries: municipal lighting masts, ports, petrochemical flare stacks, stadiums.

In the field

Case in point: a Southeast Asia stadium retrofit, 35 m masts, two 12 kN drums, 8 mm galvanized rope. After 9 months, operators reported >98% “clean layer” events and near‑zero bird‑nesting. I guess that’s what tight groove geometry buys you. One tech joked, “It finally spools like it read the manual.”

Customization options

- Drum geometry tuned to rope dia and fleet angle; synchronized dual drives.

- ATEX/IECEx motor packages for Zone 2; IP55–IP66 enclosures.

- Load cells, encoder feedback, over‑spooling limiters, pendant or PLC control.

- Marine paint systems for coastal masts; stainless fasteners as needed.

| Vendor | Groove tech | Certs | Lead time | Notes |

|---|---|---|---|---|

| LBS (China) | Lebus double‑fold line sleeve | ISO 9001; EN 14492‑1 alignment | ≈ 4–8 weeks | Sleeve replaceable; cost‑efficient |

| EU Manufacturer A | Machined Lebus pattern | CE; EN 60204‑1 | ≈ 8–12 weeks | Premium finish; higher price |

| Local Integrator B | Generic grooves | Varies | ≈ 2–6 weeks | Fast delivery; check rope lay compatibility |

Standards to tick off for a double drum winch for high mast deployment: EN 14492‑1 (power-driven hoists), ISO 4301/4309 (rope selection and discard), IEC 60204‑1 (safety of machinery—electrical), and corrosion per ISO 12944. For petrochem, consider API RP 2D guidance on lifting practices as a sanity check.

Final thought: if you’re speccing a double drum winch for high mast, don’t skimp on groove geometry and fleet-angle control. The rest—motors, paint, even brakes—is easier to standardize. The drum is where uptime is won.

Authoritative citations

- EN 14492-1: Power driven winches and hoists — Safety requirements.

- ISO 4309: Cranes — Wire ropes — Care and maintenance, inspection and discard.

- IEC 60204-1: Safety of machinery — Electrical equipment of machines.

- ISO 12944-5/6: Paints and varnishes — Corrosion protection of steel structures.

- FEM 1.001: Rules for the design of hoisting appliances (reference for duty classification).

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025