Double Drum Hydraulic Winch | Synchronized Power & Control

Field Notes on a Workhorse: Double Drum Hydraulic Winch

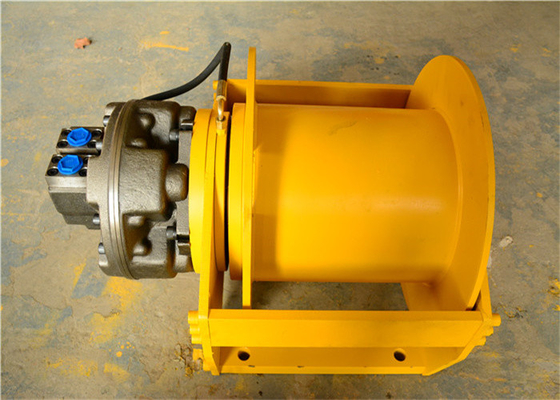

If you’ve been around deck gear or tower cranes long enough, you start recognizing the sound of a reliable drum set (the steel kind, not the musical sort). The 15-ton class double-drum units coming out of Hebei—specifically from NO.688 Zhongshan Road, Qiaoxi District, Shijiazhuang—have been popping up on offshore platforms, workover rigs, even wall-wiping machines. I’ve seen them paired on logging lines and, surprisingly, in helicopter motor winch setups. It’s a broader spread than most folks expect.

What’s trending in winches right now

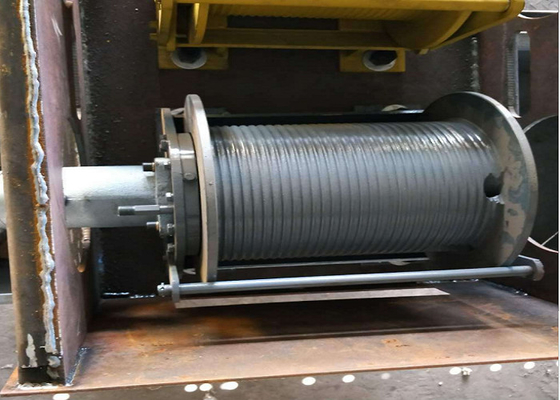

Two things: synchronized dual-line control and smarter groove management. The first is about predictable, matched payout—critical when handling anchors or tandem lifting. The second is about cable life; Lebus-type grooving keeps layers neat, which, to be honest, saves money on wire rope. Many customers say the maintenance interval feels longer than “spec sheet” conservative values.

Core specifications (typical configuration)

| Rated line pull | ≈ 150 kN (15 t) per drum, real-world use may vary |

| Line speed | 0–35 m/min (variable displacement hydraulic motor) |

| Rope capacity | Up to 500–800 m (depending on diameter/lay) |

| Grooving | Lebus-style multi-layer grooves |

| Brake | Fail-safe multi-disc hydraulic + mechanical pawl (optional) |

| Controls | Local valve block / remote PLC, load-holding counterbalance |

| Finish | Marine epoxy system, C5M optional |

| Certifications | ISO 9001; CE on request; class approvals available (ABS, DNV, CCS) |

Materials, manufacturing, and testing

• Drum/barrel: Q345B/ASTM A572-grade steel; welds ultrasonic-tested to ISO 5817 level B/C.

• Shafts/gears: 42CrMo quenched & tempered; surface hardness ≈ HRC 28–32.

• Hydraulics: load-sensing valves; nitrile or FKM seals based on medium temp.

• Testing: 125% static load hold for 10 min; functional test across speed/pressure; rope spooling test to ISO 4309 guidance.

• Expected service life: 10–15 years with routine lubrication; wire rope life per ISO 4309 inspection cycles.

Where it actually gets used

Offshore platform cranes, oil workover rigs, logging rope winders, tower and wall-cleaning machines, and yes, helicopter maintenance motor winches. The two drums let you juggle anchor handling on one side and utility lifting on the other—less swapping, more uptime. Operators like the predictable spooling; riggers like the brakes.

A quick vendor snapshot

| Vendor | Strengths | Notes |

|---|---|---|

| LBS (Hebei) | Lebus grooving, fast customization, compelling FOB pricing | FOB ≈ US $0.5–9,999 per piece; MOQs around 100; 10k pcs/month capacity |

| MacGregor | Deep marine pedigree, global service network | Premium pricing; lead times can be longer |

| TTS/NEP | Offshore packages, integration | Best for full-deck systems |

Customization checklist

Hydraulic motor displacement, dual-brake configuration, tension control (constant tension/constant speed), drum diameter/width, rope diameter, paint system (C5M for splash zones), and control interface (CANopen/Profibus). I guess the most-requested option lately is load monitoring with alarm thresholds.

Numbers that matter (field feedback)

A Middle East workover crew reported 18% fewer rope crush incidents after moving to Double Drum Hydraulic Winch with Lebus grooves; a North Sea barge logged 96.5% uptime over the first year, with only two seal swaps. Factory test data from one batch showed 0.3 mm max layer deviation at full drum—well within rope manufacturer guidance.

Why choose this unit

The draw is simple: synchronized control, robust braking, and rope-friendly grooving. The Double Drum Hydraulic Winch layout keeps operations tidy—less cross-deck chaos. Price-wise, it’s competitive, especially at MOQs of 100 and above. And the origin story—Hebei steelwork with modern QA—shows in the welds.

Compliance and standards

Designed to align with API Spec 2C for offshore cranes, DNV rules for deck machinery, ABS guidance, and rope handling per ISO 4301/4309. Ask for class witnessing if your project requires it. The Double Drum Hydraulic Winch can ship with ISO 9001 traceability packs and material certs.

Citations

- API Specification 2C – Offshore Pedestal-mounted Cranes. https://api.org

- DNV Rules for Ships/Offshore – Deck Machinery. https://www.dnv.com

- ABS Guide for Certification of Lifting Appliances. https://www.eagle.org

- ISO 4301/4309 – Cranes and Wire Ropes (Selection, Use, Inspection). https://www.iso.org

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025