Buy Drum Winch For Sale: Durable & High-Performance Solutions

Introduction to Drum Winch Systems for Industrial and Marine Applications

In industrial and marine operations, the efficiency and reliability of lifting and pulling equipment are paramount. A critical component in these demanding environments is the drum winch for sale. These robust devices are engineered to handle significant loads, facilitating operations such as anchoring, mooring, towing, and various material handling tasks. Their design integrates a rotating drum, around which wire rope or chain is spooled, driven by a powerful motor and sophisticated gearbox. The evolution of winch technology continues to emphasize precision control, enhanced safety features, and durability, catering to a diverse range of sectors from maritime and offshore energy to construction and mining. Understanding the technical intricacies and application flexibility of these systems is crucial for stakeholders seeking optimal operational performance and long-term investment value.

Industry Trends in Winch Technology

The market for industrial winches, including the specialized drum winch for sale, is experiencing dynamic shifts driven by technological advancements and evolving regulatory landscapes. Key trends include the integration of smart control systems, enhanced energy efficiency, and a focus on modular designs for easier maintenance and customization. The demand for electric winches, particularly those operating on 24V or higher DC power, is growing due to their environmental benefits and quieter operation compared to hydraulic or pneumatic systems. Furthermore, there is a push towards predictive maintenance capabilities, leveraging IoT sensors to monitor winch drum performance, motor health, and rope tension in real-time. This not only extends service life but also minimizes unexpected downtime, a critical factor in high-stakes marine and industrial applications.

- Automation and Remote Control: Advanced PLC-based control systems and wireless remote operation are becoming standard, improving operator safety and operational precision.

- Energy Efficiency: Development of more efficient motor technologies and regenerative braking systems to reduce power consumption and operational costs.

- Material Science Innovations: Use of high-strength alloys and specialized coatings for winch drum components to resist corrosion and wear, enhancing durability in harsh environments.

- Digitalization: Integration with vessel management systems and cloud-based platforms for data logging, performance analytics, and remote diagnostics.

Technical Specifications and Parameters

Detailed understanding of technical specifications is crucial when evaluating a drum winch for sale. Performance parameters directly impact functionality, safety, and longevity. Modern winches are designed with precision engineering, utilizing robust materials and advanced manufacturing techniques to meet stringent industry standards.

Key Specifications: Drum Winch Boat 24V Electric Anchor Winch

| Parameter | Value / Description |

|---|---|

| Model Number | LBS-EW24-5000 |

| Rated Line Pull | 5,000 kg (11,023 lbs) |

| Motor Voltage | DC 24V |

| Motor Power | 7.5 kW (10 HP) |

| Gear Reduction Ratio | 30:1 |

| Line Speed (No Load) | 10 m/min (33 ft/min) |

| Drum Capacity (Wire Rope) | Ø16mm x 150m (Ø0.63in x 492ft) |

| Braking System | Automatic Electro-magnetic Brake (Failsafe) |

| Control Method | Local push-button / Wireless remote (Optional) |

| Material Construction | Marine-grade Steel (SS316 for critical components), Powder Coated |

| Ingress Protection Rating | IP67 |

| Operating Temperature | -20°C to +50°C |

| Certifications | CE, ISO 9001:2015, DNV-GL Type Approval (Optional) |

These specifications highlight the robust design and high-performance capabilities essential for severe duty cycles. The integration of advanced braking systems ensures operational safety, while marine-grade materials guarantee longevity in corrosive environments.

Manufacturing Process of a High-Performance Drum Winch

The production of a reliable drum winch for sale involves a meticulous multi-stage manufacturing process, ensuring precision, durability, and adherence to international quality and safety standards. Each step, from raw material selection to final testing, is critical to the performance and service life of the winch.

Process Flow Overview:

1. Material Selection & Sourcing

High-grade marine steel (e.g., Q345B, SS316 for critical components), cast iron for drums, and high-strength alloys for gears. All materials undergo stringent chemical composition and mechanical property testing to ensure compliance with ASTM, DIN, and JIS standards, crucial for resisting fatigue and corrosion.

2. Component Manufacturing (Casting, Forging, CNC)

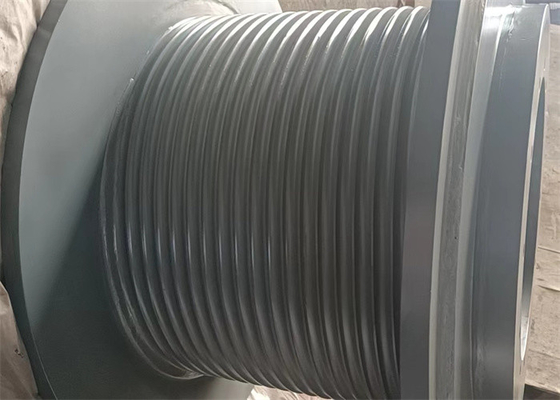

Winch drum: Precision casting or welding of rolled steel plates, followed by CNC machining for precise Lebus grooving (if applicable) to ensure optimal rope lay and extend wire rope life. Gears & Shafts: Forging for strength, followed by CNC machining and heat treatment (carburizing, quenching) to achieve high hardness and wear resistance. Frame & Housing: Laser cutting and welding of steel plates, stress relieving, and precision machining for mounting surfaces.

3. Surface Treatment & Coating

Sandblasting to SA 2.5 standard for optimal adhesion. Application of multiple layers of marine-grade epoxy primer and polyurethane topcoats, providing exceptional corrosion resistance in saline and harsh industrial environments. Galvanization or specialized anti-corrosion paints are applied as per client specifications.

4. Assembly & Integration

Assembly of gearbox, motor, braking system, control panel, and the winch drum onto the main frame. All electrical and mechanical connections are performed by certified technicians. Bearings are carefully seated, and gear mesh is checked for optimal alignment and minimal backlash.

5. Quality Control & Testing

Each unit undergoes rigorous testing including no-load and full-load performance tests, braking efficiency tests, electrical safety checks, and noise level measurements. Pressure testing of hydraulic systems (if applicable). Testing standards: ISO 9001, ANSI B30.7, ABS, DNV-GL, and Lloyd's Register guidelines, ensuring a minimum service life of 20 years under normal operating conditions.

6. Final Inspection & Documentation

Final visual inspection, functional checks, and comprehensive documentation including material certificates, test reports, and operating manuals. Packaging designed for safe transport to diverse global locations.

Target industries benefiting from these robust manufacturing standards include petrochemical for offshore platform support, metallurgy for heavy lifting and material transfer, and water supply & drainage for pumping station maintenance. The emphasis on energy-saving components like high-efficiency motors and corrosion-resistant materials directly translates to lower operational costs and extended product life, even in highly aggressive chemical environments.

Application Scenarios and Technical Advantages

The versatility of a high-quality drum winch for sale makes it indispensable across numerous demanding sectors. Its technical advantages are directly observed in improved operational efficiency, safety, and longevity.

Typical Application Scenarios:

- Marine & Offshore: Essential for anchor handling, mooring operations, towing, and deploying/retrieving subsea equipment. For instance, a double drum winch for sale is often preferred for simultaneous operations requiring independent control over two lines, like complex pipe-laying or deep-sea research.

- Construction: Used for lifting heavy structural components, pulling materials on job sites, and operating cranes.

- Mining: Hauling ore carts, positioning heavy machinery, and emergency rescue operations in underground mines.

- Logging & Forestry: Skidding logs, cable logging systems, and recovery of stuck vehicles.

- Energy Sector (Oil & Gas): Deployment of exploration equipment, umbilical handling, and maintenance of pipelines.

Technical Advantages:

- Superior Load Handling: Engineered to manage substantial static and dynamic loads, ensuring safe and effective movement of heavy assets.

- Precision Control: Advanced variable speed drives (VFDs) and accurate braking systems allow for precise positioning and controlled deployment/retrieval of loads, critical for delicate operations.

- Durability & Corrosion Resistance: Construction from marine-grade steels, robust gearboxes, and multi-layer protective coatings ensure extended service life in harsh, corrosive environments (e.g., saltwater, chemical exposures).

- Enhanced Safety Features: Overload protection, emergency stop functions, automatic fail-safe brakes, and limit switches prevent accidents and protect equipment.

- Energy Efficiency: Modern electric winches, particularly 24V models, offer significant energy savings compared to older hydraulic systems, reducing operational costs and environmental impact. For example, a typical 7.5 kW electric winch can demonstrate up to 20% greater energy efficiency than an equivalent hydraulic system, translating to substantial fuel savings over its operational lifespan.

- Reduced Maintenance: Robust design and high-quality components minimize wear and tear, leading to longer intervals between maintenance and lower lifetime costs.

Vendor Comparison and Customization Options

Choosing the right vendor for a drum winch for sale involves more than just comparing price tags. It necessitates a thorough evaluation of technical capabilities, customization flexibility, and post-sales support. Reputable manufacturers distinguish themselves through a commitment to quality, innovation, and client-centric solutions.

Vendor Comparison: Key Differentiators

| Feature | Leading Manufacturer (e.g., LBS Winch) | Generic Competitor |

|---|---|---|

| Certifications | ISO 9001:2015, CE, DNV-GL/ABS Type Approval (Optional) | Basic CE/local certifications |

| Material Quality | Marine-grade SS316, High-strength alloys for gears (verified) | Standard carbon steel, unverified alloy compositions |

| Control System | Integrated PLC, Variable Frequency Drive (VFD), Wireless Remote, Overload Protection | Basic push-button, limited safety features |

| Corrosion Protection | Multi-layer marine epoxy/polyurethane coating, optional galvanization | Standard industrial paint, susceptible to harsh environments |

| Customization | High degree: drum size, power source, line pull, speed, control type, special features (e.g., Lebus grooving, auto-tension) | Limited standard options only |

| After-Sales Support | Global service network, 24/7 technical support, readily available spare parts, extended warranty | Local/limited support, delayed spare parts, basic warranty |

Customized Solutions: Tailoring the Winch to Your Needs

Recognizing that no two industrial operations are identical, leading manufacturers offer extensive customization for their drum winch for sale range. This ensures that the winch seamlessly integrates into existing infrastructure and performs optimally for specific tasks.

- Power Source Adaptation: Options for electric (AC/DC, various voltages), hydraulic, or pneumatic drives, matching available power infrastructure.

- Winch Drum Design: Custom drum sizes, Lebus grooving for precision wire rope spooling, and options for single or a double drum winch for sale configuration for complex multi-line operations.

- Line Pull & Speed: Tailored to specific load requirements and operational speeds, from high-speed light duty to low-speed heavy-duty pulls.

- Control Systems: Integration of advanced features like auto-tensioning, constant speed control, multi-point remote control, and integration with vessel/plant management systems.

- Environmental Enhancements: Special coatings for extreme temperatures, explosion-proof motors for hazardous zones (ATEX certified), and noise reduction measures for sensitive environments.

- Mounting & Footprint: Custom base plates, deck mounting arrangements, and compact designs to fit space-constrained installations.

Application Case Studies & Customer Feedback

Real-world application demonstrates the reliability and effectiveness of a well-engineered drum winch for sale. These case studies highlight the practical benefits and operational improvements achieved by various clients.

Case Study 1: Offshore Platform Supply Vessel

A major offshore energy company required a robust and reliable anchoring and mooring system for its new fleet of Platform Supply Vessels (PSVs) operating in the North Sea. They opted for a custom-built double drum winch for sale solution, each drum capable of 80-ton line pull and equipped with automatic tension control and a Lebus grooved winch drum. The winches were integrated into the vessel's dynamic positioning system and certified by DNV-GL. The client reported a 15% reduction in anchoring time due to precise control and the efficiency of the Lebus grooving in managing wire rope, coupled with a significant decrease in rope wear, directly extending rope service life by an estimated 25%.

"The customized drum winch system exceeded our expectations in terms of reliability and operational efficiency. The DNV-GL certification provided essential peace of mind for our critical offshore operations. We particularly appreciate the robust corrosion resistance in the harsh North Sea environment." - Chief Engineer, Trident Marine Services.

Case Study 2: Hydroelectric Dam Maintenance

A hydroelectric power plant required a specialized winch drum system for lifting and positioning large intake gates during maintenance periods. Given the precise vertical alignment needed and the corrosive freshwater environment, a 24V DC electric drum winch with a precise variable speed drive and an IP67 rating was selected. The winch featured a compact design to fit within limited space and included a specialized braking system for controlled lowering. The system allowed for gate positioning with sub-centimeter accuracy, significantly reducing maintenance downtime from 48 hours to 30 hours per gate, illustrating the value of bespoke engineering.

"The electric drum winch provided the precision and reliability we needed for critical dam gate operations. Its corrosion-resistant build has proven invaluable, showing no signs of degradation after two years of continuous exposure to humid conditions." - Operations Manager, Riverbend Hydro.

Ensuring Trustworthiness: FAQ, Lead Time, Warranty & Support

Transparency in product information, delivery, and post-purchase support builds confidence. Here's what to expect when considering a high-quality drum winch for sale.

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for a custom drum winch?

A: Standard models typically have a lead time of 4-6 weeks from order confirmation. Customized solutions, depending on complexity and specific component sourcing, generally require 8-12 weeks. Expedited options may be available upon request.

Q: What warranty coverage is provided for your winches?

A: We offer a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty plans up to 36 months are available, along with comprehensive service contracts.

Q: How do you ensure product quality and compliance?

A: All our winches undergo rigorous multi-stage quality control, including material verification, in-process inspections, and full-load factory acceptance testing (FAT). We adhere to international standards such as ISO 9001 and CE directives, with third-party classification society certification (e.g., ABS, DNV-GL, Lloyd's Register) available for marine and offshore applications.

Q: What kind of after-sales support do you provide?

A: Our comprehensive after-sales support includes 24/7 technical assistance, global spare parts availability, on-site commissioning and training, and scheduled preventative maintenance services. Our goal is to ensure continuous, optimal performance of your equipment throughout its lifecycle.

Lead Time & Fulfillment Details:

Our manufacturing facility operates under a lean production model to optimize efficiency without compromising quality. We maintain strategic inventories of critical components to facilitate faster assembly for standard models. For bespoke projects, a detailed project timeline is provided, outlining design, manufacturing, testing, and shipping milestones. We partner with reputable logistics providers to ensure timely and secure global delivery, offering various shipping options including sea freight and air cargo.

Warranty Commitments:

Our robust warranty reflects our confidence in the engineering and manufacturing quality of every winch drum system. Beyond the initial warranty period, we offer extended service agreements that include routine inspections, preventative maintenance, and priority access to technical support and spare parts. This commitment ensures minimal operational interruptions and sustained performance.

Customer Support Information:

Our dedicated customer support team is available around the clock to assist with inquiries, technical troubleshooting, and spare parts orders. We provide multilingual support to cater to our diverse global clientele. For direct assistance, please refer to the contact details provided on our official website, or utilize our online support portal for comprehensive resources and FAQs.

Conclusion

The selection of a high-performance drum winch for sale is a strategic decision that directly impacts operational efficiency, safety, and long-term cost-effectiveness in demanding industrial and marine environments. By prioritizing advanced engineering, robust materials, adherence to international standards, and comprehensive post-sales support, businesses can ensure they invest in equipment that delivers unparalleled reliability and performance. The continuous evolution of winch technology, driven by automation, energy efficiency, and customization, promises even greater capabilities for future applications.

References

- International Organization for Standardization (ISO). ISO 9001:2015 Quality management systems – Requirements.

- American National Standards Institute (ANSI). ANSI B30.7-2016 Base Mounted Drum Hoists.

- DNV-GL. Rules for Classification of Ships, Offshore Units and Structures.

- ABS (American Bureau of Shipping). Guide for Certification of Lifting Appliances.

- "Advances in Marine Winch Technology for Offshore Operations," Journal of Ocean Engineering and Technology, Vol. 15, No. 3, 2022.

- "Energy Efficiency and Automation in Industrial Lifting Equipment," Industrial Automation Review, Vol. 8, No. 1, 2023.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025