Alloy Steel LBS Rope Groove Drum Leather|Professional Design

Field Notes on a Small Part With Big Impact: The LBS Rope Groove Drum “Leather”

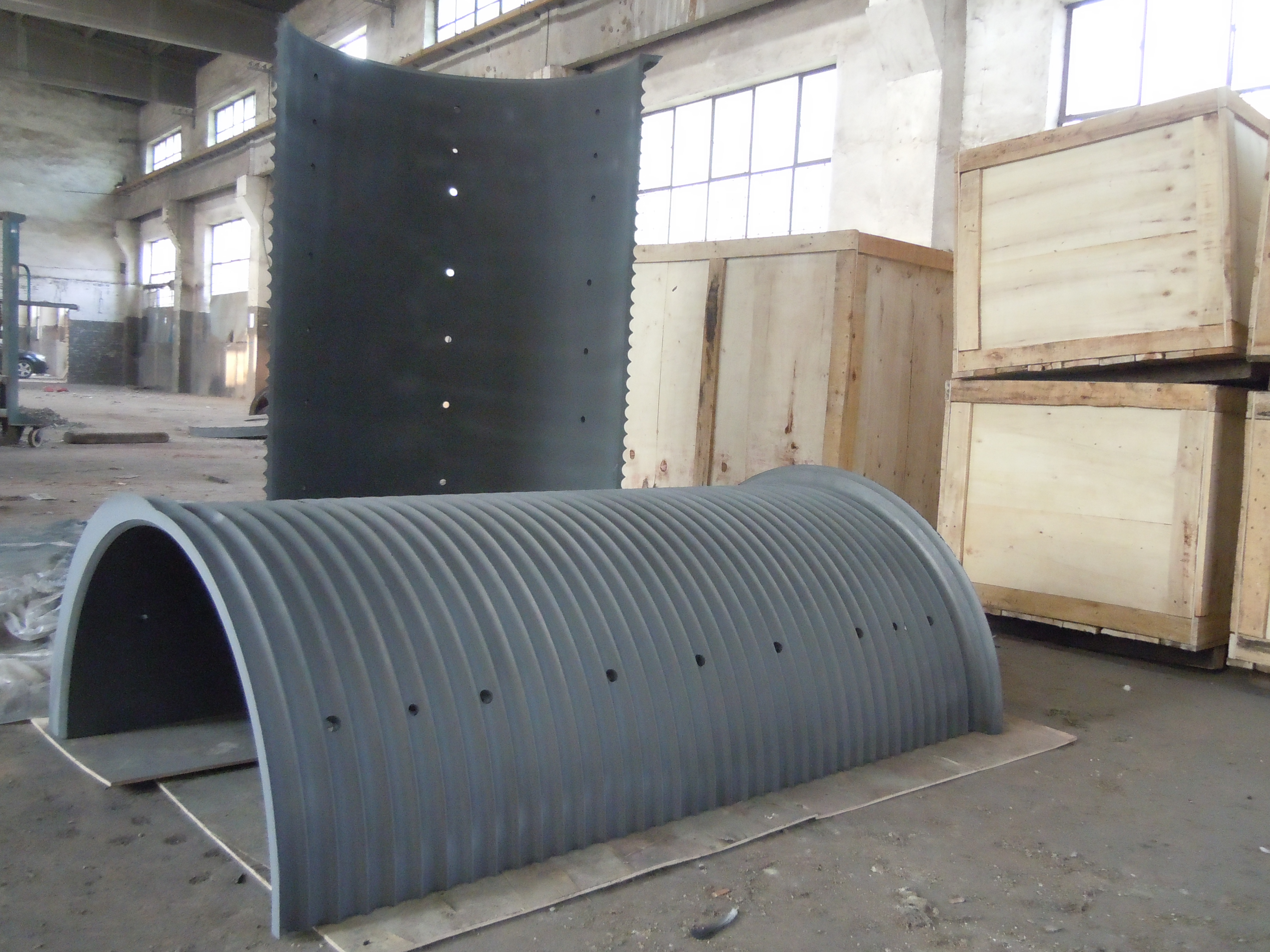

If you handle lifting, winching, or subsea lines for a living, you already know the ugly truth: wire ropes fail at the drum first. That’s why I’ve been watching products like the Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather for a while. It’s a split, replaceable sleeve that turns a smooth or spiral drum into a proper LBS (Lebus-style) rope groove system—without scrapping the entire drum. To be honest, the cost-per-life-cycle math is surprisingly good.

What’s trending in drums and ropes

Across ports, mining, and offshore hoists, the trend is toward predictable spooling, less crushing, and faster changeovers. LBS groove geometry—alternating inclined and parallel grooves—has become the shorthand for extending rope life. Many customers say they’ve seen fewer bird-nests after switching. I guess the bigger story is modularity: a split “leather” sleeve that you bolt on, swap later, and keep the main drum in service. Downtime drops; accountants smile.

How it’s made (short version)

- Materials: alloy steel (e.g., 42CrMo4/4140) with MTC 3.1 available.

- Method: drum skin is machined to the LBS pattern, then split into two matched halves.

- Heat treat: normalized/quenched and tempered; optional induction-hardened groove lands.

- Finishing: shot-peen, anti-corrosion coating (zinc-rich or epoxy), roughness controlled.

- Testing: UT (ISO 17640), MT (ISO 9934), hardness (ISO 6508-1), salt spray (ASTM B117).

| Spec | Typical Value (≈, real-world use may vary) |

|---|---|

| Material grade | 42CrMo4 / AISI 4140, per EN 10204 3.1 |

| Hardness | HRC 28–36 core; up to ≈40 HRC on groove lands (option) |

| Groove geometry | LBS alternating inclined/parallel; pitch matched to rope lay |

| Diameter compatibility | ≈200–2,500 mm |

| Rope sizes | 8–64 mm (larger on request) |

| Surface roughness | Ra ≤ 3.2 μm (ISO 4287) |

| Corrosion protection | Primer + epoxy topcoat; ≥ 240 h salt spray (ASTM B117) |

| Service life impact | Rope life +30–100% vs. smooth drums (duty dependent) |

| MOQ / Capacity | 100 pcs; ≈10,000 pcs/month |

| FOB price | US $0.5–9,999 / piece (spec-dependent) |

Where it’s used

Shipboard winches, port cranes, tower cranes, shaft hoists, mobile recovery winches, pipe-lay tensioners. In fact, any place a layered rope wants to wander or crush. One crane superintendent told me, “We swapped the sleeve, not the drum—one weekend, back on hire Monday.”

| Vendor | Groove accuracy | Replaceable | Docs | Lead time |

|---|---|---|---|---|

| Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather | High (CNC, verified) | Yes, split halves | ISO 9001, EN 10204 3.1 | Around 3–6 weeks |

| Generic Vendor A | Medium | Sometimes | Basic CoC | 6–10 weeks |

| Generic Vendor B | Medium–High | Yes | 3.1 on request | 4–8 weeks |

Customization

- Groove pitch/angle matched to rope construction (per ISO 4309 guidance).

- Sleeve thickness and split orientation for existing drums.

- Anti-corrosion system for marine classes (DNV lifting guidance compliant areas).

- Witness inspection, 3.1/3.2 documents, and fit-up jigs for quick installs.

Real-world snapshots

Case: Port gantry crane—48 mm rope, 1,200 h/month. After installing Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather, rope discard interval moved from ≈8 to ≈14 months; spooling temperature dropped ≈6–8°C (IR camera), indicating less friction.

Case: Underground hoist—32 mm non-rotating rope. Operator feedback: “Layer transition calmed down.” Post-install UT and runout checks stayed within ±0.15 mm after 9 months.

Compliance, documents, and origin

Quality system: ISO 9001:2015. Inspection: UT/MT, dimensional reports, hardness charts, coating DFT. Certificates: EN 10204 3.1 available; 3.2 on request with third-party witness. Designed to support rope care practices per ISO 4309 and offshore lifting expectations in DNV-ST guidelines.

Origin: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. Many buyers drop by for factory FATs—there’s coffee, usually strong.

Authoritative references:

- ISO 4309:2017 Cranes — Wire ropes — Care, maintenance, installation, examination and discard.

- DNV-ST-0378: Standard for Offshore and Platform Lifting Appliances.

- EN 10204:2004 Metallic products — Types of inspection documents.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 6508-1: Metallic materials — Rockwell hardness test.

- ISO 17640 / ISO 9934: UT and MT testing of steel components.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025