120v Electric Winch with Synthetic Rope | Safe, Durable Pulling Power

Introduction to Advanced Electric Winch Solutions

In the demanding B2B landscape, the efficiency, reliability, and safety of material handling equipment are paramount. Modern industrial and marine operations increasingly rely on robust winching systems to execute critical lifting, pulling, and positioning tasks. A standout innovation in this sector is the 120v electric winch with synthetic rope, which combines high performance with enhanced safety features. This advanced solution offers a compelling alternative to traditional wire rope systems, delivering superior operational flexibility and reduced maintenance across a spectrum of industrial applications.

The integration of synthetic rope with a reliable 120V electric motor represents a significant leap forward, providing a lighter, stronger, and safer option for various B2B needs, from construction sites to marine platforms. This article delves into the technical intricacies, manufacturing excellence, diverse applications, and inherent advantages of these state-of-the-art winching systems.

Current Industry Trends in Electric Winch Technology

The global winch market is experiencing a significant transformation, driven by demands for increased operational safety, enhanced efficiency, and reduced environmental impact. Key trends include:

- Synthetic Rope Adoption: The shift from steel wire rope to high-performance synthetic ropes, such as Dyneema or Spectra, is a major trend. Synthetic ropes offer superior strength-to-weight ratios, are safer to handle (no metal splinters, less kinetic energy if snapped), and float on water, making them ideal for marine applications.

- Electrification and Energy Efficiency: There's a growing preference for electric winches over hydraulic or pneumatic systems due to their cleaner operation, lower energy consumption, and quieter performance. The development of advanced motor controls ensures precise speed and torque management.

- Higher Load Capacities: While the 120v electric winch with synthetic rope is versatile, the market also sees a strong demand for heavy-duty units like the 10000 lb electric winch, addressing needs for larger industrial and offshore projects.

- Voltage Versatility: While 120V models are popular for their accessibility, specialized applications often require higher voltage options, such as an electric pulling winch 240v, to handle sustained, heavy loads and integrate seamlessly into larger industrial power grids.

- Smart Winch Systems: Integration of IoT and remote monitoring capabilities for predictive maintenance, operational analytics, and enhanced safety protocols.

- Corrosion Resistance: Emphasis on materials and coatings that withstand harsh environments, particularly in marine and offshore applications, extending service life and reducing lifecycle costs.

These trends underscore an industry-wide commitment to innovation, safety, and sustainable operations, with products like the 120v electric winch with synthetic rope at the forefront of this evolution.

Technical Specifications and Parameters

The performance of a 120v electric winch with synthetic rope is defined by a combination of robust engineering and advanced material science. Key components include the electric motor, gearbox, brake system, drum, and the synthetic rope itself.

Product Specification Table: Marine Platform Electric Winch (LBS-120V-SR Series)

| Parameter | Specification |

|---|---|

| Model | LBS-MPEW-SR-2T |

| Rated Line Pull (1st layer) | 2 Ton (4,400 lbs) - Adjustable up to 10000 lb electric winch configurations |

| Motor Voltage | 120V AC, Single Phase (Optional 240V AC, 3 Phase for heavy duty) |

| Motor Power | 3.0 kW (4 HP) |

| Rope Type | High-Modulus Polyethylene (HMPE) Synthetic Rope |

| Rope Diameter | 10 mm (0.4 inch) |

| Rope Length | 50 meters (164 feet) - Customizable |

| Line Speed (1st layer) | 9-12 m/min (30-40 ft/min) |

| Brake Type | Electro-magnetic, Failsafe disc brake |

| Gearbox Type | Planetary Gear Reduction |

| Control System | Remote Pendant Control, Wireless Remote (Optional) |

| Drum Type | Rope Groove Drum for optimal rope lay |

| Ingress Protection | IP55 (Motor), IP67 (Control Enclosure) |

| Operating Temperature | -20°C to +45°C (-4°F to +113°F) |

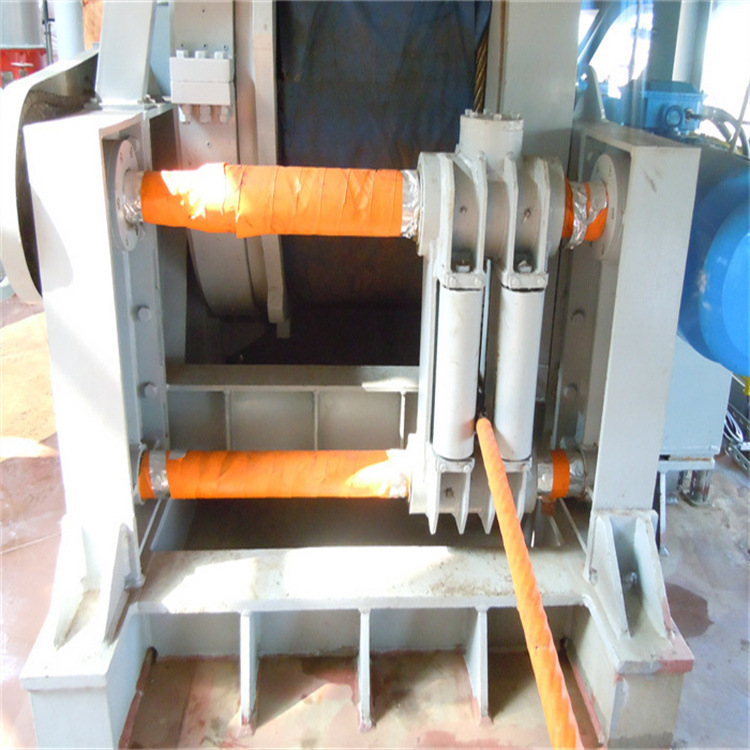

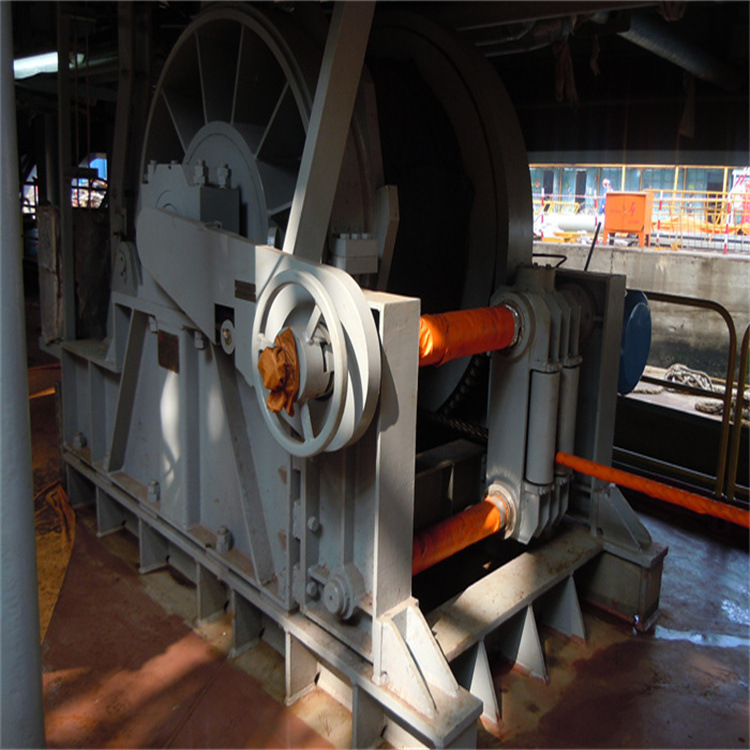

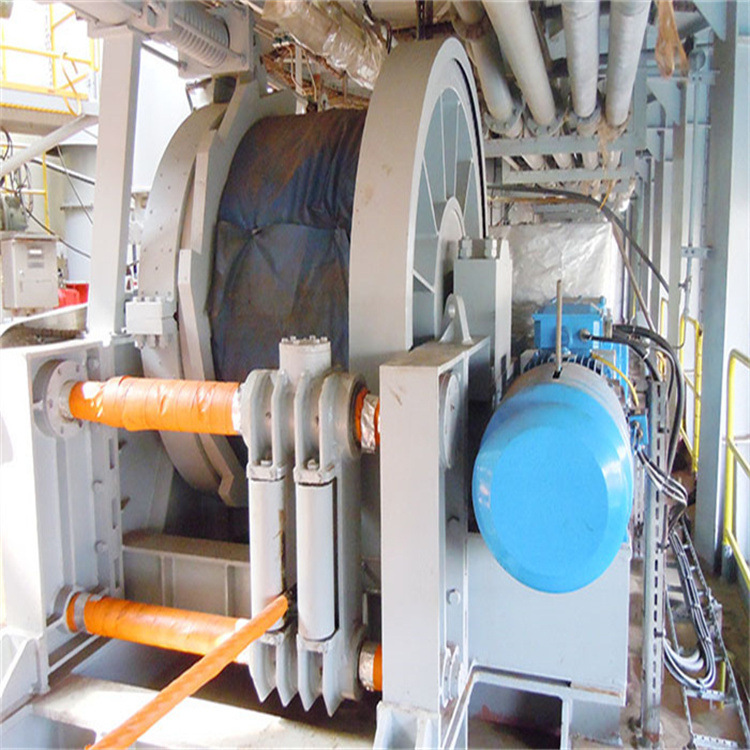

These specifications highlight the robust design and engineering precision inherent in modern winching solutions, ensuring optimal performance and safety in diverse operational environments. The double broken line rope groove drum design is particularly critical for marine applications, preventing rope overlap and ensuring consistent spooling.

Detailed Manufacturing Process Flow of a 120v Electric Winch with Synthetic Rope

The production of a high-quality electric winch involves a meticulous multi-stage process, ensuring durability, precision, and performance. Our manufacturing adheres to stringent international standards such as ISO 9001 and ANSI B30.7, guaranteeing a superior product with an extended service life, typically exceeding 15 years under proper maintenance.

Process Steps:

-

Material Procurement & Inspection:

High-grade alloy steels (e.g., 40Cr, 42CrMo) are sourced for gears, shafts, and drums. Cast iron (e.g., HT250) or ductile iron (e.g., QT450-10) is used for casings. Synthetic rope (HMPE) from certified suppliers undergoes rigorous tensile strength and abrasion resistance tests. Incoming materials are verified against specifications using spectral analysis and ultrasonic testing.

-

Casting/Forging of Components:

Winch drum, gear blanks, and brake components are either cast or forged. Forging processes enhance material grain structure, improving strength and fatigue resistance, crucial for the robust design of a 120v electric winch with synthetic rope.

-

CNC Machining:

Precision CNC machining shapes the drum, shafts, gears, and housing to tight tolerances. The rope groove drum, in particular, requires high precision to ensure optimal rope spooling and minimize wear on the synthetic rope. Gear teeth are precisely cut and ground for smooth, efficient power transmission.

-

Heat Treatment:

Critical components like gears and shafts undergo heat treatment processes (e.g., carburizing, quenching, tempering) to achieve desired hardness, wear resistance, and toughness, extending the operational life of the winch.

-

Surface Treatment & Coating:

Components are sandblasted and then coated with marine-grade epoxy paint or galvanized finishes to provide superior corrosion resistance, especially vital for applications in petrochemical, metallurgy, and water supply & drainage industries, where harsh environmental conditions are common. This significantly contributes to energy saving by reducing friction and material degradation.

-

Motor and Electrical System Assembly:

The 120V AC electric motor, chosen for its efficiency and reliability, is integrated with the gearbox. Electrical components, including control panels, circuit breakers, and wiring, are assembled and tested for insulation resistance and operational safety.

-

Final Assembly:

All major sub-assemblies (motor, gearbox, drum, frame, brake system) are integrated. Bearings are installed, and lubrication points are checked. The synthetic rope is meticulously spooled onto the drum.

-

Rigorous Testing & Quality Control:

Each winch undergoes extensive testing:

- Load Testing: Winches are tested at 125% of their rated capacity for static and dynamic loads, per ISO 8686 standards.

- Brake Performance Testing: Verifying holding capacity and smooth engagement/disengagement.

- Motor & Electrical Performance: Current draw, temperature rise, speed consistency, and control responsiveness.

- Noise & Vibration Analysis: Ensuring optimal operational acoustics and structural integrity.

- Synthetic Rope Inspection: Post-load test inspection for any signs of wear or damage.

-

Documentation & Certification:

Each unit is accompanied by detailed operational manuals, maintenance guides, and relevant certifications (e.g., CE, Lloyd's Register approval for marine models). This thorough process ensures that every 120v electric winch with synthetic rope delivered meets the highest standards of quality and reliability.

Key Technical Advantages of Synthetic Rope Winches

The integration of synthetic rope profoundly enhances the operational profile of the 120v electric winch with synthetic rope, offering several distinct advantages over traditional steel wire rope systems:

- Superior Strength-to-Weight Ratio: Synthetic ropes are significantly lighter than steel wire ropes of equivalent breaking strength. This reduces the overall weight of the winch system, making it easier to transport and install. For example, a synthetic rope can be up to 8 times lighter than steel for the same load capacity, contributing to a lighter 10000 lb electric winch.

- Enhanced Safety: In the event of a rope failure, synthetic ropes store much less kinetic energy compared to steel, leading to a significantly reduced recoil "snap-back" hazard. This drastically lowers the risk of severe injury to personnel. They also eliminate the danger of metal splinters and burrs during handling.

- Corrosion Resistance: Unlike steel wire, synthetic ropes are highly resistant to rust and corrosion from saltwater, chemicals, and UV exposure. This makes them ideal for harsh marine, petrochemical, and wastewater treatment environments, minimizing degradation and maintaining structural integrity over time.

- Flexibility and Ease of Handling: Synthetic ropes are more flexible and pliable, making them easier to spool, knot, and splice. This translates to quicker deployments, simplified maintenance, and reduced operator fatigue.

- Reduced Abrasion on Equipment: The softer nature of synthetic rope causes less wear and tear on winch drums, fairleads, and other contact points, extending the lifespan of these components.

- Non-Conductive Properties: For applications where electrical insulation is a concern, such as near power lines or in specialized industrial settings, synthetic rope offers an inherent non-conductive property that steel wire does not.

These advantages collectively contribute to a safer, more efficient, and more cost-effective winching solution, particularly for operations requiring precision, reliability, and robust performance in challenging conditions.

Diverse Application Scenarios

The versatility and robust design of a 120v electric winch with synthetic rope make it an indispensable tool across a broad spectrum of industrial and commercial applications:

- Marine & Offshore: Ideal for mooring small vessels, deploying/retrieving scientific instruments, handling fishing nets, or utility tasks on offshore platforms. The corrosion resistance and flotation properties of synthetic rope are crucial here. It can also be integrated into larger systems requiring an electric pulling winch 240v for heavier marine equipment.

- Petrochemical Industry: Used for precision positioning of equipment during maintenance, lifting components within hazardous areas, or assisting in pipeline deployment. The non-sparking nature of synthetic rope reduces risks in explosive environments.

- Metallurgy: Facilitating the movement of heavy raw materials, positioning molds, or assisting in furnace maintenance. The robust design handles the intense heat and heavy loads often associated with this sector.

- Water Supply & Drainage: Employed for lowering and raising pumps, valves, and monitoring equipment into wells, sumps, or sewage treatment facilities. The synthetic rope's resistance to water and chemicals ensures long-term reliability.

- Construction & Utilities: Lifting building materials, pulling cables through conduits, or positioning structural elements on job sites. Portable 120V units provide flexible power options.

- Logistics & Warehousing: Assisting in loading/unloading heavy cargo, pulling pallets, or positioning goods in tight spaces.

- Mining: For various pulling and hauling tasks within mines, especially where light weight and corrosion resistance are beneficial, contributing to a safer and more efficient underground operation.

These diverse applications underscore the adaptability and critical role of the 120v electric winch with synthetic rope in enhancing operational efficiency and safety across vital B2B sectors.

Vendor Comparison: LBS Winch vs. Competitor

When selecting a 120v electric winch with synthetic rope, a thorough vendor comparison is essential. LBS Winch stands out due to its commitment to quality, customization, and comprehensive after-sales support. Below is a comparison table highlighting key differentiators:

Electric Winch Vendor Comparison

| Feature | LBS Winch (Typical) | Generic Competitor B (Typical) |

|---|---|---|

| Rope Groove Drum Design | Standard Double Broken Line Rope Groove Drum (Optimized for synthetic rope) | Smooth drum or basic single groove (May cause uneven spooling) |

| Motor Protection Rating | IP55/IP56 (Standard for harsh environments) | IP44/IP54 (Limited protection) |

| Brake System | Dual Redundant Electro-magnetic Failsafe Disc Brake | Single mechanical brake or basic spring-loaded brake |

| Customization Options | Extensive (Voltage, rope length, control type, coating, load sensors) | Limited, standard configurations only |

| Certifications & Standards | ISO 9001, CE, ANSI B30.7, Marine Class Society approvals (e.g., DNV, LR) | Basic CE, often lack specific industry certifications |

| Warranty & Support | 24-36 month comprehensive warranty, global technical support, spare parts availability | 12-18 month standard warranty, regional support only |

| Material Quality (Frame/Drum) | High-strength structural steel with marine-grade coatings | Standard industrial grade steel, basic powder coating |

This comparison underscores LBS Winch's commitment to delivering higher performance, enhanced safety, and greater long-term value, crucial for demanding B2B operations. The focus on specialized drum design for synthetic rope and robust certification further distinguishes our offerings.

Customized Solutions for Unique Requirements

Recognizing that standard products may not always meet the unique challenges of every industrial application, we specialize in providing customized solutions for our 120v electric winch with synthetic rope systems. Our engineering team collaborates closely with clients to tailor winches that integrate seamlessly into their specific operational environments.

- Voltage & Power Modifications: While 120V models are common, we can adapt designs for an electric pulling winch 240v or other industrial voltages, and increase motor power to meet higher load demands, such as achieving a 10000 lb electric winch capacity with enhanced line speeds.

- Rope Specifications: Custom lengths, diameters, and types of synthetic rope can be specified to match specific load requirements, abrasion resistance needs, or environmental conditions.

- Control System Integration: Options include advanced PLC-based controls, wireless remote systems with extended range, emergency stop protocols, and integration with larger facility automation systems.

- Environmental Adaptations: Specialized coatings for extreme marine or chemical environments, explosion-proof motors for hazardous zones, or extreme temperature operation packages.

- Mounting & Frame Design: Bespoke frame designs to fit specific installation footprints, or specialized mounting brackets for mobile applications or platforms.

- Safety Features: Integration of overload protection systems, automatic rope tensioning, layer counters, and advanced limit switches to enhance operational safety.

Our agile design and manufacturing capabilities ensure that even highly specialized requirements are met with precision engineering and robust construction, providing a truly bespoke winching solution.

Application Case Studies & Client Success

Our commitment to delivering high-performance winching solutions is validated by successful deployments in diverse industrial settings:

Case Study 1: Offshore Platform Equipment Deployment

A leading energy company required a reliable system for deploying and retrieving subsea sensors and maintenance tools from a semi-submersible offshore platform. Traditional wire rope systems proved problematic due to corrosion and significant weight. We provided a customized 120v electric winch with synthetic rope, equipped with an IP67 rated motor and a specialized control panel. The synthetic rope's buoyancy and superior corrosion resistance significantly reduced deployment times by 30% and improved safety by eliminating metal fatigue concerns. The lighter winch also reduced structural load on the platform, leading to overall operational cost savings.

Case Study 2: Municipal Water Treatment Plant Pump Maintenance

A municipal water treatment facility needed an efficient and corrosion-resistant winch for raising and lowering heavy submersible pumps for routine maintenance in wastewater sumps. A standard 10000 lb electric winch with steel rope posed rust risks and required frequent inspection. Our solution involved a custom-fabricated electric pulling winch 240v with an HMPE synthetic rope and a stainless-steel frame. This system demonstrated exceptional longevity in the highly corrosive environment, reducing downtime by 40% annually for winch-related issues and significantly enhancing worker safety during pump handling operations.

Customer Feedback:

"The synthetic rope winch supplied by LBS has revolutionized our marine deployment process. The reduced weight and increased safety margin are invaluable, and the 120V power makes it incredibly versatile for our smaller vessels."

— Operations Manager, Global Marine Services Inc.

Authoritativeness, Certifications, and Trust

Our commitment to engineering excellence and client satisfaction is underscored by rigorous adherence to international standards and a proven track record.

- Certifications: All winches, including our 120v electric winch with synthetic rope products, are manufactured under ISO 9001:2015 certified quality management systems. Individual components and finished products adhere to relevant standards such as CE, ANSI B30.7, and often obtain specific marine class society approvals (e.g., DNV, Lloyd's Register) for marine applications. Our motors comply with IEC and NEMA standards.

- Years of Service & Experience: With over two decades in the material handling equipment industry, we have supplied winching solutions to hundreds of B2B clients globally, accumulating extensive experience in diverse and challenging environments.

- Partner Clients: Our clientele includes major players in the petrochemical, shipbuilding, civil engineering, and offshore energy sectors, demonstrating trust in our product reliability and service capability.

- Testing Data & Analysis: We maintain comprehensive test data for all products, including detailed load test reports, material certifications, and performance graphs that are available upon request, offering full transparency and verifiable product performance.

- Quality Assurance: Each winch undergoes a multi-point inspection and testing protocol before shipment, ensuring compliance with design specifications and performance parameters.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: What is the typical service life of a 120v electric winch with synthetic rope?

- A: With proper maintenance and adherence to operational guidelines, our winches are designed for a service life of 15-20 years. Synthetic ropes typically have a lifespan of 5-10 years, depending on usage intensity and environmental exposure, and are easily replaceable.

- Q: Can I use a 120V winch for heavy-duty applications?

- A: While 120V winches are highly capable for their designed load, for continuous heavy-duty operations or loads exceeding specific limits, we recommend consulting our engineers. Options like the electric pulling winch 240v or a 10000 lb electric winch configuration may be more suitable to ensure optimal performance and longevity.

- Q: How does synthetic rope perform in harsh weather conditions?

- A: Synthetic ropes (HMPE) are highly resistant to UV degradation, moisture absorption, and extreme temperatures (both hot and cold). They do not freeze and become brittle like steel wire can, making them exceptionally reliable in diverse climates.

- Q: Is installation complicated for these winches?

- A: Our winches are designed for straightforward installation. Each unit comes with a detailed installation manual. We also offer technical support and, for larger projects, can provide on-site supervision or commissioning services.

Lead Time & Fulfillment

Standard models of our 120v electric winch with synthetic rope typically have a lead time of 4-6 weeks from order confirmation to shipment. Custom-engineered solutions may require 8-12 weeks, depending on the complexity of specifications. We utilize established global logistics partners to ensure timely and secure delivery to your specified location, with comprehensive tracking and communication throughout the fulfillment process.

Warranty Commitments & Customer Support

We stand behind the quality and reliability of our products with a comprehensive 24-month warranty on all mechanical and electrical components, starting from the date of delivery. Our commitment extends beyond the sale through dedicated after-sales support:

- Technical Assistance: Our team of experienced engineers is available for technical consultations, troubleshooting, and operational guidance via phone, email, or video conferencing.

- Spare Parts Availability: We maintain a readily accessible inventory of genuine spare parts to minimize downtime for maintenance or repairs.

- Maintenance Services: We offer guidance on preventative maintenance schedules and can arrange for qualified technicians for on-site service or inspections as required.

- Training Programs: Operator and maintenance personnel training can be arranged to ensure optimal and safe operation of our winching systems.

Conclusion

The 120v electric winch with synthetic rope represents a pivotal advancement in industrial and marine material handling. By combining the efficiency and control of electric power with the unparalleled safety, strength, and durability of synthetic rope, these winches offer a superior solution for a wide array of demanding B2B applications. From critical offshore operations to precision tasks in petrochemical plants, the advantages of reduced weight, enhanced safety, superior corrosion resistance, and simplified handling translate directly into improved operational efficiency and reduced total cost of ownership. Our commitment to meticulous manufacturing, stringent quality control, and comprehensive after-sales support ensures that clients receive not just a product, but a reliable, high-performance solution tailored to their specific needs.

References

- ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- ANSI B30.7 - Winches. American Society of Mechanical Engineers.

- DNV GL Rules for Classification of Ships - Part 4 Chapter 2 Lifting Appliances. Det Norske Veritas.

- ASTM D4014 / D4014M - Standard Specification for Plain and Reinforced Load-Bearing Elastomeric Bridge Pads. American Society for Testing and Materials.

- The Engineering ToolBox - Properties of Metals. Engineeringtoolbox.com.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025