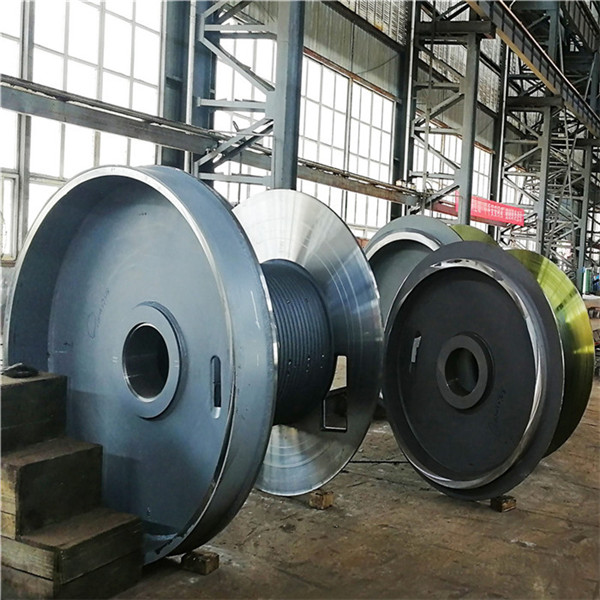

일반적인 비홈(매끄러운) 드럼 및 나선형 홈 드럼과 비교했을 때, 홈이 있는 강철 북 has obvious advantages in the neat winding of multi-layer steel wire rope. lebus groove makes the winding of steel wire rope more smooth and the load between layers is evenly distributed, reduces the irregular, disorderly winding and rope biting in the process of steel wire rope arrangement, reduces the damage of steel wire rope, prolongs the service life of steel wire rope, improves the safety of equipment operation, and avoids the shutdown time of mechanical equipment due to disorderly rope replacement.

The disadvantage of LBS rope groove drum is that it is more complex, so it is a little more expensive than the spiral rope groove drum. However, this additional cost is quickly compensated for by the savings in wire rope, which is expensive and takes up production time to replace.

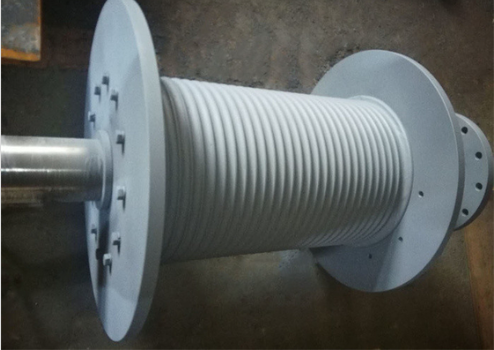

In order to reduce costs, we produce LEBUS SLEEVES, which are also manufactured to the required size of the wire rope. The material can be either steel or nylon, butt-welded or bolted onto the reel. This ensures that the wire rope is wrapped in orderly layers on the reel. When the wire rope can also be replaced, only SLEEVE can be replaced instead of the reel, greatly saving the cost and time

the lebus groove system is formed into a sleeve with groove shape, also known as LEBUS sleeve.After finishing, it is cut into two pieces along the direction of 180 degrees, and finally welded or bolt with the drum body. This method can reduce machining time and improve machining efficiency.When the rope groove needs to be replaced for a long time, the outer sleeve can be replaced directly, saving 500% of the cost.

our production of lebus groovef drums and grooved drum sleeves assembly, now widely used in petroleum machinery, mining machinery, ships, ports, lifting machinery, lifting machinery, etc., and with daqing oilfield, shengli oilfield, dagang oilfield, zhongyuan oilfield, liaohe oilfield oilfield, nanyang oil factory, big companies such as sany, established a long-term, stable relations of cooperation, Products are also exported to the United States, Canada, Brazil and so on. Our factory can design and manufacture various specifications of lebus groove drum, lebus grooved sleeves and winch according to the requirements of users, but also can provide on-site installation.